Home > Market > Other Regions > Here

Potential Map for the Installation of Concentrated Solar Power Towers in Chile

2020.04.29 From: Energies

Authors

Catalina Hernández 1,2, Rodrigo Barraza 1,*, Alejandro Saez 1, Mercedes Ibarra 2 and Danilo Estay 1

Danilo Estay 1

1 Department of Mechanical Engineering, Universidad Técnica Federico Santa María, Av. Vicuña Mackenna 3939,

Santiago 8320000, Chile

2 Fraunhofer Chile Research Foundation, General del Canto 421, of. 402, Providencia Santiago 7500588, Chile

* Author to whom correspondence should be addressed.

Abstract

This study aims to build a potential map for the installation of a central receiver concentrated solar power plant in Chile under the terms of the average net present cost of electricity generation during its lifetime. This is also called the levelized cost of electricity, which is a function of electricity production, capital costs, operational costs and financial parameters. The electricity production, capital and operational costs were defined as a function of the location through the Chilean territory. Solar resources and atmospheric conditions for each site were determined. A 130 MWe concentrated solar power plant was modeled to estimate annual electricity production for each site. The capital and operational costs were identified as a function of location. The electricity supplied by the power plant was tested, quantifying the potential of the solar resources, as well as technical and economic variables. The results reveal areas with great potential for the development of large-scale central receiver concentrated solar power plants, therefore accomplishing a low levelized cost of energy. The best zone is located among the Arica and Parinacota region and the northern part of the Coquimbo region, which shows an average cost of 89 USD/MWh, with a minimum of 76 USD/MWh near Copiapó.

Keywords: concentrated solar power; levelized cost of energy; central receiver; solar energy; solar potential

1. Introduction

Concentrated solar power (CSP) plants are distinguished over other solar technologies because they provide energy, power and ancillary services to the electricity market, aspects that other technologies do not have within their commercial scheme. The CSP technology is characterized with clean electricity production (without greenhouse gases and particulate matter emissions), low variable cost, high capacity factor when thermal energy storage (TES) is considered and a high potential of contributing towards a robust electrical grid. Regarding ancillary services, the CSP plants have the feature of managing their inter-hour operation with a low-cost operation, fast boot time and operation, rotative machine inertia, primary and secondary frequency control and tension control [1].

The commercialization of CSP is limited by its relatively high cost of electricity generation. In comparison with other CSP technologies (parabolic trough and linear Fresnel), the CSP tower technology is able to work with higher temperatures to achieve greater efficiencies in the power block where the thermal energy is converted into electricity, which results in a lower power generation cost [2,3]. The economic feasibility of energy related projects requires thorough testing by means of adequate estimation techniques in order to estimate the electricity generation cost regardless of the technology [4,5]. Some authors [6,7] propose a mathematical expression for the levelized cost of electricity (LCOE) that estimates the average net present cost of electricity generation during the power plant lifetime.

The LCOE of CSP tower plants is affected by several factors. One of the most important is the available direct normal irradiation (DNI) [8,9,10] over 1800 kWh/m2-year [11,12]. Belgasim et al. [13] showed that the LCOE may be affected by site parameters including land topography and water and grid accessibility. Some authors [8,14,15,16] indicate the relevance of financial conditions as one of the major cost drivers of the LCOE. Guedez et al. [17], in a case study in Seville (Spain), obtained good results using large power blocks (over 100 MWe) with medium-to-large thermal storage systems. Emes et al. [18] studied the impact of the wind speed on the LCOE, as the windspeed impacts the electricity production when it exceeds the heliostat’s stow velocity.

Chile is recognized as one of the countries with the highest average annual solar radiation [19], specifically in the Atacama Desert, where there is high direct radiation and the sky is clear over 300 days per year. Marzo et al. [20] developed a map that identifies locations with high potential for the development of CSP in Chile. The selected locations present daily average DNI over 1800 kWh/m2 and land slopes below 3%. The forecast LCOE for CSP tower plant in Chile varies from 142.8 (2014) to 73.5 USD/MWh (2050) according to Parrado et al. [9]. In the same study, Chile showed a 47% and 30% lower LCOE than Spain and the USA, respectively. These results revealed that northern Chile is a suitable location to implement CSP tower plants. Several companies have shown interest in placing their CSP plants in northern Chile; however, the only project currently under construction is the CSP-PV plant called Cerro Dominador, a project that considers 100 MW of PV and 110 MW of CSP [21].

At present, the Chilean grid does not have relevant CSP participation. One of the major obstacles of CSP technology is that it needs to be economically competitive in terms of the cost of electricity generation. Further information is required to address tech-economic uncertainty. The reported LCOEs for a CSP tower plant shows high variability [22] and limited studies have evaluated Chilean conditions. Selecting the most appropriate site is a key factor for a successful CSP project. DNI seems to be a key criterion but is not the only relevant parameter. As mentioned, geographic conditions should be considered, as should infrastructure conditions such as water grid and road access. The site selection requires geographical and economic condition analysis [23]. In order to promote CSP, it is critically important to select appropriate sites, based on realistic local costs, climate data, geographic conditions and access to preexisting infrastructure. This work conducts an economic analysis in terms of the levelized cost of electricity LCOE for a 130 MW CSP tower plant including thermal energy storage TES tested throughout the Chilean territory. This work defines a solid base that predicts the levelized cost of electricity for a CSP tower plant and selects economically feasible locations by means of a potential map. This analysis aims to decrease uncertainties and increase the penetration of CSP tower technology in Chile.

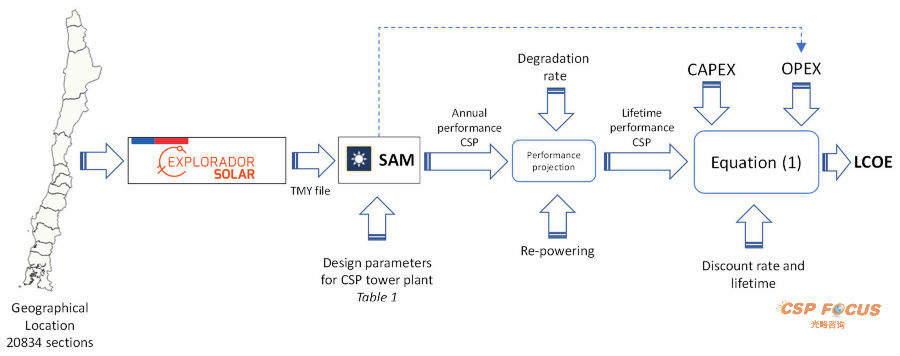

2. Methodology for LCOE Map Construction

A simple method for the estimation of the LCOE of a CSP tower plant is tested throughout the Chilean territory. As presented in Figure 1, the method is comprised of three steps. First, the solar resource and environmental data was collected for each location by means of a typical meteorological year (TMY) files collected from the Solar Explorer [24]. Second, a CSP tower plant was modeled with the available information of the Copiapó Solar Project [25] that will be installed in the Atacama Desert in Chile (27°21′ S 70°19′ W). The solar field was optimized for this location, maximizing annual electricity generation and defining the number and distribution of heliostats using a System Advisor Model (SAM) [26]. The performance of this plant was evaluated in each location using SAM under the local climate conditions provided by the specific TMY file obtaining the annual performance of the CSP tower plant for each location under study. The estimation method employed to assess the lifetime performance of the plant considered an annual degradation rate of the heliostat’s mirror reflectivity that decreases the annual electricity generation. An increase in the annual electricity generation was also observed between the 15th and the 19th year of operation as a result of the replacement of heliostat’s mirrors, boosting the heliostat mirror reflectivity (re-powering). Finally, the LCOE was estimated by integrating the present value of the capital and operational costs during the plant’s lifetime and the total electricity generation of the power plants life cycle. Some costs were subject to their geographical location and were determined as a function of their distance to major cities.

Figure 1. Methodology for levelized cost of electricity (LCOE) map building.

3. Solar Resource and Environmental Data

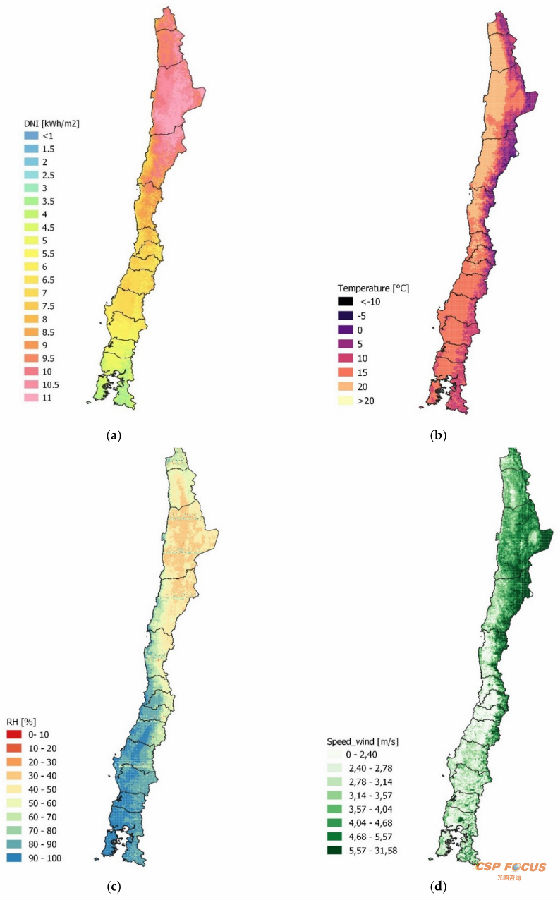

Chile is divided into 20,834 sections. Each of these sections was identified with the geographic coordinates (latitude and longitude) of its center. A TMY (DNI, temperature, relative humidity (RH), pressure, wind direction and speed) was generated for each section using the online Solar Explorer tool (Explorador Solar) developed by the Chilean Ministry of Energy [24]. The radiation database and its accuracy is explained in [27]. Figure 2 presents maps of the average daily values of DNI (a), ambient temperature (b), relative humidity (c) and wind speed (d) according to the TMY files generated by means of the Solar Explorer for each section under study. The places with higher DNI are in northern Chile. Values for the average daily DNI range between 10 and 11 kWh/m2. The available DNI has a direct impact on electricity production of the CSP tower plant. The same locations present average daily temperatures between 15 °C and 20 °C and relative humidity ranging between 30% and 50%. Both ambient temperatures and relative humidity are relevant because they impact the performance of the dry condenser used in the power block of the CSP tower plant effecting the CSP tower plants efficiency. The northern regions of Chile present wind speeds varying from low, medium and high wind values. The locations with wind speed greater than 10 m/s require special attention because these exceed the limit of wind speed required to avoid damage in the heliostats. When the wind speed limit is exceeded, the heliostats adopt a low wind resistance position, thus no electricity is generated.

Figure 2. Average daily values of (a) direct normal irradiation (DNI) (b) ambient temperature (c) relative humidity (d) wind speed in Chile according to typical meteorological year (TMY) data, generated using the Solar Explorer [13].

4. CSP Tower Plant Modeling and Performance

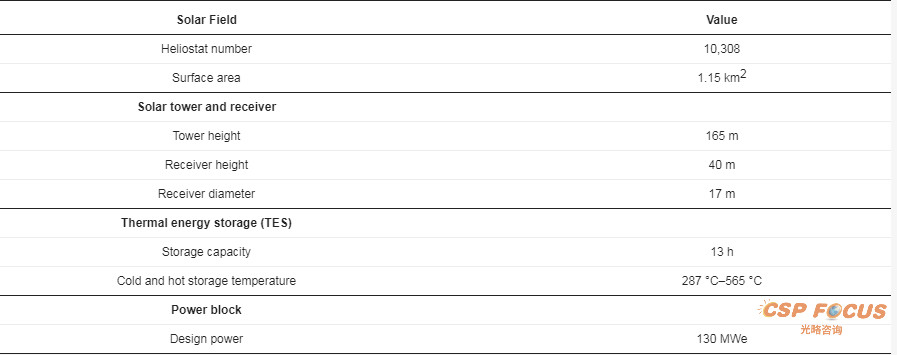

Figure 3 shows a conventional CSP tower. This technology redirects and concentrates the incoming direct normal radiation DNI in a solar receiver using two axis tracker mirrors (also called heliostats). A heat transfer fluid HTF is heated in the solar receiver, accumulating thermal energy. In the steam generator, the warmed HTF is used to produce steam, which is expanded in the steam turbine of the power block (Rankine steam cycle) to generate electricity. The CSP tower may be competitive when thermal energy storage TES is included, and the system may generate electricity without solar radiation (13 h). Molten salt is used as HTF in a two-tank system, where the cold tank contains salt at 287 °C and the second at 565 °C. The proposed CSP tower plant is based on the available information of the Copiapó solar project [25]. The CSP tower plant input design parameters are shown in Table 1.

Figure 3. Schematic of a concentrated solar power (CSP) tower system.

Table 1. Input design parameters for CSP tower plant [25].

The electricity production of a CSP tower plant is subject to the available DNI and optical losses (cosine, block and shading, atmospheric attenuation, spillage and soiling) affecting the DNI on its path towards the solar receiver. The average reflectivity of the heliostats can be reduced by the presence of dust (soiling). It is possible to maintain an average reflectivity in the heliostats if optimum cleaning frequency is used. The atmospheric attenuation represents the average loss of reflected radiation caused by the absorption of atmospheric particles (carbon dioxide, water and particulate matter) in the path from each heliostat to the solar receiver. The atmospheric attenuation depends on the level of aerosol present in each location. There is not much information available regarding these two factors (soiling and atmospheric attenuation) within the Chilean territory. This study established an initial mirror reflectivity of 90%, an estimated daily soiling rate of 0.29% [28] and an average atmospheric attenuation loss of 2%. The other optical losses (cosine, block and shading and spillage) were determined for each location from the simulations performed in SAM. Solar Pilot was the integrated tool from SAM used to characterize solar power towers optical losses including cosine, block and shading and spillage [29].

In many systems, water is used to cool the Rankine steam cycle; however, the Atacama Desert is one of the driest places in the world, and the center and northern regions of Chile suffer high water stress. Therefore, the use of water is limited and an air based condenser (dry cooling) is required. Using dry cooling decreases the water requirement of power plants by 90%, although its investment cost is higher, and the power cycle efficiency decreases.

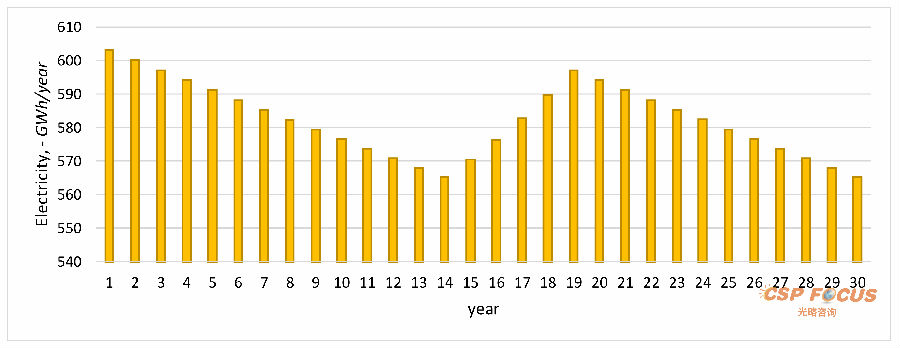

The solar fields distribution was defined by SAM. The software optimized the annual performance for the site (27°21′ S 70°19′ W) located in the Chilean Atacama Desert. The annual performance for the CSP tower plant was evaluated for each location using SAM under local climate conditions by means of TMY files determining the annual electricity production. The electrical losses from the transmission line between the CSP tower and the selected substation were subtracted from the annual energy yield. In addition, an annual degradation rate of 0.5% was considered regarding the initial reflectivity of the mirrors. This degradation has multiple causes including site climatic conditions, geological parameters and parameters related to the nature of the mirrors surfaces [30]. Figure 4 shows the annual electricity production during the lifetime of the CSP tower plant. In the 15th year, the electricity production of the plant increases, as old mirrors are replaced by new ones. This re-powering of the plant is performed between the 15th and 19th year of operation, replacing 20% of the heliostat mirrors on a yearly basis.

Figure 4. Annual electricity production during the lifetime of the CSP tower plant, a location in Arica and Parinacota region (−17.5398865, −69.5092869).

5. LCOE Model for CSP Tower

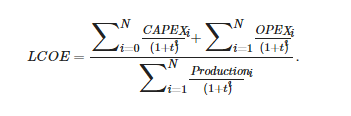

The LCOE represents the electricity generation cost during the entire lifetime of the power plant. This parameter is useful to compare different technologies in terms of economic viability. Equation (1) shows the mathematical expression for LCOE as reported by Hernandez-Moro and Martinez-Duart [7]. It is the ratio in terms of present value during the lifetime of the plant considering all the costs required to install and operate a specific technology and the total electricity production. Production represents the electricity generated annually, CAPEX refers to the capital expenditures, and OPEX denotes the operational expenditures. The discount rate (t) is assumed to be 7% and the lifetime (i) for the CSP tower is 30 years [31]. The LCOE is calculated in nominal base [32].

5.1. CAPEX

The CAPEX required to build a CSP tower plant includes site preparation, construction of the solar field, solar tower, solar receiver, TES and power block, among other expenses. The CAPEX was determined based on several studies [33,34] and by adjusting the reported values according to information provided by local developers of CSP tower plants. The solar fields CAPEX was determined considering 122 USD/m2 of heliostats. The solar tower and receiver’s capital costs were valued in 13 and 63 MMUSD (Million U.S. dollars), respectively. The investment in thermal energy storage was calculated using 22 USD/kWh of thermal storage considering that the HTF was provided by a local supplier. The power block investment cost was estimated at 685 USD/kW of the electrical peak power. The site preparation and contingency related CAPEX were estimated at 5% each. Table 2 shows the summary of the CAPEX required for a CSP tower plant of 130 MWe with 13 h of thermal storage capacity. The solar field, solar receiver, TES and power block represent over 85% of the required investment in the CSP tower plant.

Table 2. CAPEX required for a CSP tower plant of 130 MWe with 13 h of TES [33,34].

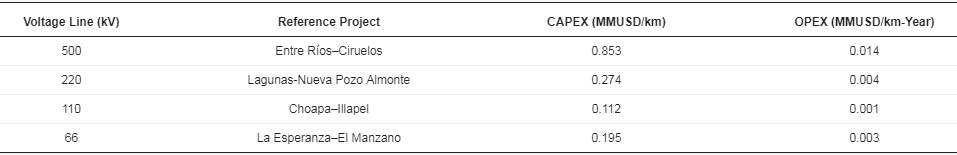

The Chilean national electric grid features lines of 500, 345, 220, 154, 110 and 66 kV, and the most common lines are 500, 220, 110 and 66 kV. A line with higher voltage reduces electrical losses but is more expensive. The model selects a connection between the CSP tower plant with a near substation optimizing the LCOE. The independent variables are distance and substation voltage. For example, in a specific location the models simulation found that the closest substation had 66 kV lines, although there was a 110 kV line in the next substation. By optimizing the LCOE, the model determined that a connection to the 110 kV line is more convenient, as the cost of construction of the 110 kV line (requiring longer distance and higher initial investment) does not exceed the energy losses of the 66 kV line.

The model considers the construction of a dedicated line from the CSP tower plant to the selected substation (SS) that optimizes the LCOE. The substations considered as alternatives in the model are listed in the National Electric Coordinator [35]. The energy losses in the triphasic lines are calculated using Equation (2), where R is the electrical resistance (R = 0.05759 Ω/km) and I is the electrical current. The electrical current is determined using Equation (3), where S is the apparent electrical power and VLL is the line to line voltage.

Table 3 shows the CAPEX and OPEX in the transmission line as a function of distance. The OPEX includes the operational and maintenance costs.

Table 3. CAPEX and OPEX in the transmission lines as a function of distance

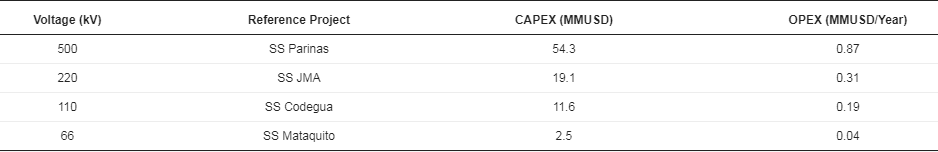

A substation plant is required in the CSP tower plant. The required CAPEX and OPEX for the substation are listed in Table 4 according to the voltage level of the line to be connected.

Table 4. CAPEX and OPEX for the substation according to the voltage level of the line to be connected [36].

The CAPEX required to build roads may be studied using two approaches. The first, assessing the distance needed to connect the CSP tower plant and the selected substation, and the second, the connection to a major road which connects the CSP tower plant with the closest city. In this study, the first approach was used, as a road that follows the transmission line presents some advantage as it improves the routes conditions to perform maintenance tasks to the transmission line. The construction of an asphalt road in a rural sector with 1 km of extension and 7 m of width was quoted, representing a value of 0.329 MMUSD/km.

In addition, a recurring CAPEX equal to 10% of the investment of the CSP tower plant was used in replacement of the heliostat’s mirrors. The replacement involved only the mirrors, as the structures and remaining components of the heliostats were not replaced. Consequently, 10% (replacement of mirrors/solar field) of the total investment in the CSP tower plant was considered. This replacement began in the 15th year of operation and ended in the 19th year of operation where 20% of the mirrors were replaced each year.

5.2. OPEX

The OPEX in a CSP tower plant corresponds to operation and maintenance costs, human resources for operational and administrative purposes, transport and water required to clean the heliostats and run the Rankine cycle.

The OPEX related to the operation and maintenance of the CSP tower plant was composed by a fixed cost of 66 USD/kW/year and a variable cost of 3.5 USD/MWh/year, provided by SAM. In addition, the OPEX of the operation, maintenance and administration of the dedicated transmission line and the substation is presented in Table 3 and Table 4.

A CSP tower plant of 130 MWe requires 40 employees, in which eight work in administrative duties and 32 are operators. In a continuous operation mode (24 h and 365 days), 7 × 7 work shifts are assumed, where employees work 7 days and +7 days off-duty. Each shift has one supervisor, three engineers and four technicians. Regarding the above, the operational cost in human resources is 0.043 MMUSD per shift. In the administrative duties, the operational cost is 0.062 MMUSD per month.

In addition, employee shuttle services were considered from the city to the CSP tower plants location. A bus with capacity for 20 people was considered with a yield of 11.4 km per liter of fuel. The price of fuel was established according to the nearest major city, and was estimated according to the information provided by the Ministry of Energy [37].

The OPEX also considers the water required to run the power block and clean the heliostats. SAM provides the water consumption for the operation of the power block, considering local environmental variables. The water required for cleaning is directly proportional to the soiling rate of the solar field. The goal is to keep an average reflectivity on the solar field; the water required to maintain the solar field is determined as a function of the yearly cleaning frequency. When an average soiling rate of 0.29% per day [28] is considered, the heliostats should be cleaned 35 times every year, estimating a water consumption of 29,110 m3/year. The water is transported by tanker trucks from the closest city to the power plant. The associated transport cost is defined by local quotes and is calculated as a function of the distance (0.384 USD/m3-km). The price of the water is based on quotations of water from inverse osmosis treatment plants (demineralized water), with a price of 5.65 USD/m3.

6. Results and Discussion

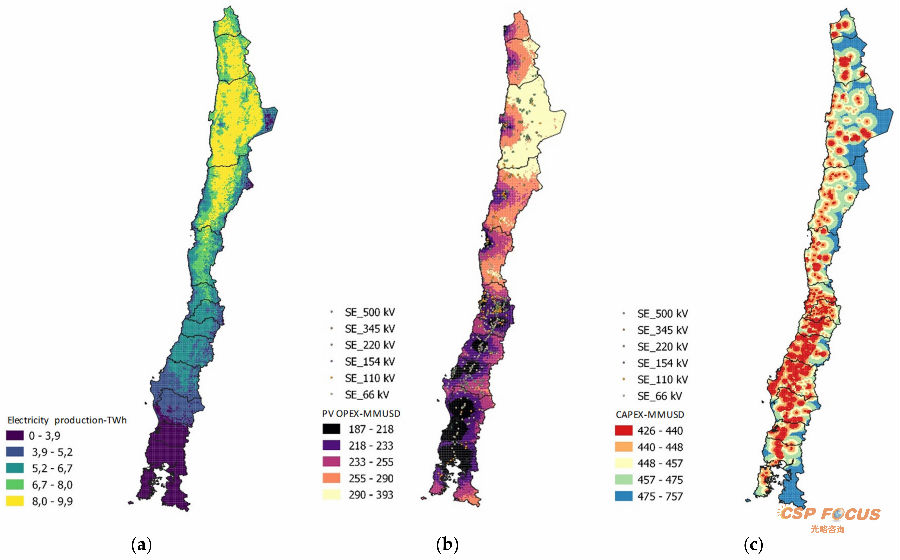

Figure 5a presents the total electricity production during the lifetime of the CSP tower plant. The total electricity production map follows a similar trend to the DNI map shown in Figure 2a. A lower energy yield in zones with high DNI may also be associated with elevated windspeed forcing the heliostat field to adopt a secure position, reducing energy production. Figure 5b shows the present value of the OPEX costs during the project’s lifetime. The OPEX is affected by the distance of the project to major cities. Transport service and water requirements for the power block operation and heliostat’s mirror cleaning are also affected. The transmission line operational and maintenance costs are dependent on the substations distance. The lower OPEX values are located near the selected major cities, as the transportation costs involved in the power plants operation are reduced. Figure 5c presents the CAPEX costs associated with installation of the CSP tower plant. The CAPEX is also subject to its locations, and construction costs of transmission lines and roads. Lower CAPEX values are found in locations where the grid interconnection and road connections are readily available.

Figure 5. Maps of the total electricity production during the lifetime of the CSP tower plant (a), the present value of OPEX costs in the lifetime (b), and the CAPEX costs involved in the installation of the power plant (c).

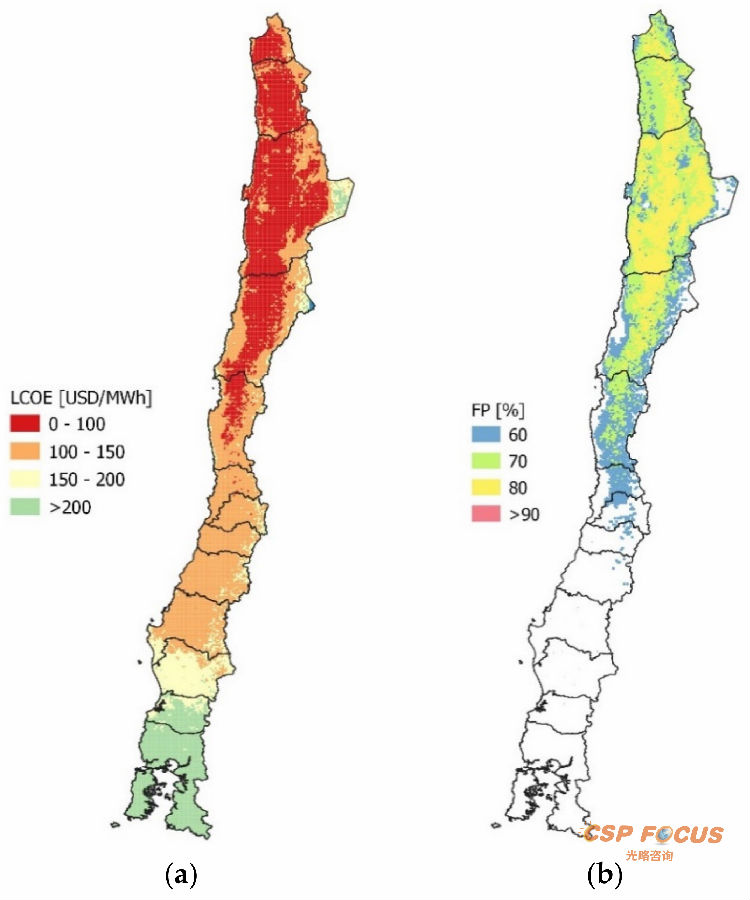

Figure 6a displays the LCOE potential map for CSP tower plant installation throughout the Chilean territory. Northern Chile, from the Arica and Parinacota region to the northern part of the Coquimbo region, presents a higher potential because of its lower LCOE value. This area is distinguished by having high DNI and low presence of clouds throughout the year. The map considers the following ranges: below 100 USD per MWh (red zone), 100–150 USD/MWh (orange zone), 150–200 USD/MWh (yellow zone) and above 200 USD/MWh (green zone). Most of northern Chile has an LCOE under 100 USD/MWh representing 33% of the 20,834 analyzed locations. In addition, more than half of the country (from the north to the Biobio region) has an LCOE under 150 USD/MWh, representing 72% of the Chilean territory. Less than 15% of the studied locations have a LCOE above 200 USD/MWh.

Figure 6. Maps of the (a) LCOE in ranges 0–100, 100–150, 150–200 and >200 USD/MWh. (b) Capacity factor (FP) over 60%.

Figure 6b, presents the map of the capacity factor of a CSP tower plant in the Chilean territory, where the locations with a capacity factor over 60% are presented. CSP tower plants with a capacity factor above 80% have a performance equivalent to coal power plants. These are located in the north of Chile, excluding coastal regions and the Andes mountain range.

In Figure 2a, it can be observed that northern Chile presents impressive high average daily DNI (including the east border closest to the Andes mountain range), excluding the coastal regions. As observed in Figure 2d, the average wind is strongest in the east border near the Andes mountain range. This indicates that more hours during the year are likely to present wind speeds greater than 10 m/s. The selected wind stow speed is 10 m/s, in order to protect heliostats according to studies [18,38,39]. The CSP power plant cannot operate if wind speeds are above the stow velocity, even if though the solar radiation presents optimal values. Therefore, different capacity factors may be observed in Figure 6b in zones with similar annual average daily DNI values. Therefore, the analysis revealed that the most significant parameters that impact the LCOE are the average annual DNI and wind speed.

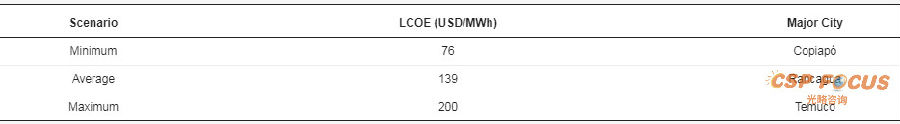

Table 5 displays three scenarios: minimum, average and maximum LCOE. The minimum LCOW is located 30 km from Copiapó, with a value of 76 USD/MW. The average LCOE is found near Rancagua with 139 USD/MWh. The locations with high LCOE are in the southern regions near Temuco.

Table 5. LCOE of characteristic locations throughout the Chilean territory.

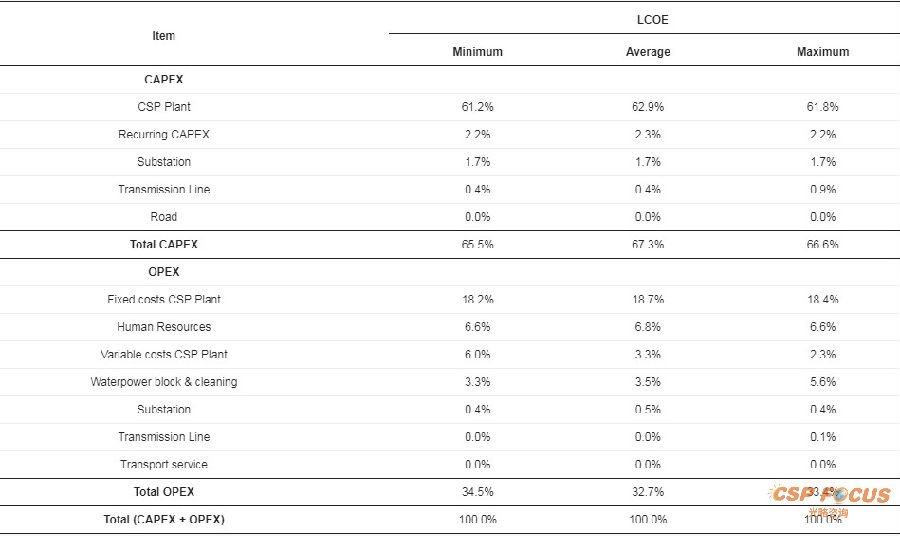

Table 6 shows the CAPEX and the present value of the OPEX through the expected lifetime (30 years) of the CSP tower plant, considering three representative scenarios (minimum, average and maximum LCOE). There is no significant variation among the three cases as they are all located near major cities. The CAPEX represents near 67% of the investment, and the OPEX the remaining 33%. According to Table 2, the main CAPEX costs are associated with the CSP tower plant (62%) where the solar field, solar receiver, TES and power block construction represent the most relevant expenses. The recurring CAPEX and substation costs represent the second greatest expenses, reaching close to 2% of the investment. In the OPEX, the fixed operational costs of the CSP tower plant represents close to 18%. Employee’s salaries represents 7% of the operational costs. The variable operational costs of the CSP tower plant and the transport cost of purified water have a smaller impact. When the LCOE reaches lower values, the operational cost increases its relative weight, and therefore its impact. Thus, the OPEX estimation must be calculated with greater accuracy.

Table 6. Distribution of the investment cost CAPEX and the operational OPEX for the three LCOE scenarios.

7. Sensitivity Analysis

A sensitivity analysis was performed. The variations in the LCOE as a function of thermal energy storage time was studied. Figure 7 shows the results for the three representative cases. The dashed line displays the results with 13 h of TES (base case scenario). When the TES time increases, the LCOE rises. However, the apparent optimum TES time is under 13 h. For the minimum LCOE case, the optimum time of TES is 12 h, and the LCOE is reduced by 0.67% (from 75.9 to 75.4 USD/MWh). In the average LCOE case, the optimum time of TES is also 12 h with a reduction in the LCOE of 0.14%. In the maximum LCOE case, the optimum time of TES is reached with 11 h of storage, reducing the LCOE by 1.26% (from 200.3 to 197.8 USD/MWh). The greater impact of the TES in locations with high LCOE may be explained by a lower availability of the solar resource, as the investment in TES generates a small revenue.

Figure 7. LCOE as a function of time of thermal energy storage.

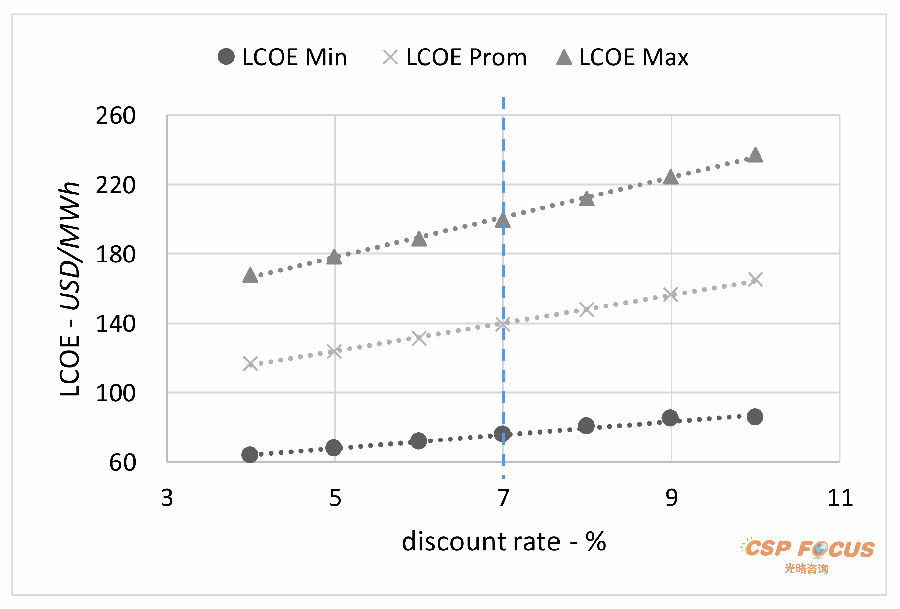

The impact of the discount rate over the LCOE was also studied. In Figure 8, the base case scenario is shown with a dashed line, which considers a discount rate of 7%. The discount rate shows a linear relationship with the LCOE in the analyzed range for the three tested scenarios. In the zone where the LCOE is low, it is possible to achieve a LCOE of 64 USD/MWh when the discount rate is 3%. If the discount rate is higher (10%), the LCOE might rise up to 86 USD/MWh.

Figure 8. LCOE as a function of discount rate.

8. Conclusions

CSP tower plants require high DNI and moderate wind speed (to avoid damage to the heliostats). Locations with an inclination under 3% are preferred and access to water sources, grid interconnection and highways motorways have a significant influence on the LCOE. The presence of nearby major cities is also a relevant parameter as these grant access to certificated employees, potentially improving the performance of the CSP tower plant.

In Chile, the zone with the highest potential is located from the north of the Arica and Parinacota region to the north of the Coquimbo region. These locations present high solar irradiation (over 9.5 kWh/ m2 -day), wind speeds under 10 m/s during most of the year, an average LCOE of 89 USD/MWh and a minimum LCOE of 76 USD/MWh (near Copiapó). The LCOE calculation considers a 7% discount rate and a lifetime of 30 years. The CAPEX is the most relevant cost in the LCOE for the CSP tower plants representing 66% of the total investment. The sensitivity analysis also indicates a strong impact of the projects discount rate.

The methodology proposed in this study is not limited to the Chilean territory. It could be used to identify niche areas for the development of CSP projects worldwide. It could also be a powerful tool to determine the most appropriate location to install a CSP tower plant in order to achieve a specific capacity factor or LCOE.

Author Contributions

Conceptualization, C.H., R.B., A.S., and M.I.; methodology, C.H., R.B., A.S., and M.I.; formal analysis, C.H., R.B., A.S., M.I., and D.E.; investigation, C.H., R.B., A.S., M.I., and D.E.; writing—original draft preparation, C.H., R.B., A.S., M.I., and D.E.; writing—review & editing, C.H., R.B., A.S., M.I., and D.E.; supervision, R.B. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

The authors express their gratitude for the financial support from ANID/Fondap/15110019 “Solar Energy Research Center”-SERC-Chile. C.H. acknowledges the generous financial support provided by CORFO (Corporación de Fomento de la Producción) under the project 13CEI2-21803.

Acknowledgments

The implementation of the study is part of the Master Thesis in the program Energy Economics (Magister en Economía Energética, MEE) at the Universidad Técnica Federico Santa María.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| i | Lifetime |

| R | Electrical resistance |

| t | Discount rate |

| CAPEX | Capital expenditures |

| CO2 | Carbon dioxide |

| CSP | Concentrated solar power |

| DNI | Direct normal irradiation |

| FP | Capacity factor |

| HTF | Heat transfer fluid |

| LCOE | Levelized cost of electricity |

| MMUSD | Million U.S. dollars |

| OPEX | Operational expenditures |

| PV | Photovoltaic |

| RH | Relative humidity |

| SAM | System Advisor Model |

| SS | Substation |

| TES | Thermal energy storage |

| TMY | Typical meteorological year |

| USD | U.S. dollars |

References

Gallardo, Felipe Modelación de CSP, Diseño y Cálculo de Inputs Para Pre-despacho. Available online: http://www.comitesolar.cl/wp-content/uploads/2017/08/Disen%CC%83o-CSP-Felipe-Gallardo-20170824.pdf (accessed on 15 November 2019).

Mehos, M.; Turchi, C.; Vidal, J.; Wagner, M.; Ma, Z.; Ho, C.; Kolb, W.; Andraka, C.; Kruizenga, A. Concentrating Solar Power Gen3 Demonstration Roadmap; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2017. [Google Scholar]

Hinkley, J.T.; Hayward, J.A.; Curtin, B.; Wonhas, A.; Boyd, R.; Grima, C.; Tadros, A.; Hall, R.; Naicker, K. An analysis of the costs and opportunities for concentrating solar power in Australia. Renew. Energy 2013, 57, 653–661. [Google Scholar] [CrossRef]

Zhao, Z.-Y.; Li, Z.-W.; Xia, B. The impact of the CDM (clean development mechanism) on the cost price of wind power electricity: A China study. Energy 2014, 69, 179–185. [Google Scholar] [CrossRef]

Frisari, G.; Stadelmann, M. De-risking concentrated solar power in emerging markets: The role of policies and international finance institutions. Energy Policy 2015, 82, 12–22. [Google Scholar] [CrossRef]

Hernández-Moro, J.; Martínez-Duart, J.M. CSP electricity cost evolution and grid parities based on the IEA roadmaps. Energy Policy 2012, 41, 184–192. [Google Scholar] [CrossRef]

Hernández-Moro, J.; Martinez-Duart, J.M. Analytical model for solar PV and CSP electricity costs: Present LCOE values and their future evolution. Renew. Sustain. Energy Rev. 2013, 20, 119–132. [Google Scholar] [CrossRef]

Zhuang, X.; Xu, X.; Liu, W.; Xu, W. LCOE Analysis of Tower Concentrating Solar Power Plants Using Different Molten-Salts for Thermal Energy Storage in China. Energies 2019, 12, 1394. [Google Scholar] [CrossRef]

Parrado, C.; Marzo, A.; Fuentealba, E.; Fernández, A.G. 2050 LCOE improvement using new molten salts for thermal energy storage in CSP plants. Renew. Sustain. Energy Rev. 2016, 57, 505–514. [Google Scholar] [CrossRef]

Purohit, I.; Purohit, P. Technical and Economic Potential of Concentrating Solar Thermal Power Generation in India. Renew. Sustain. Energy Rev. 2017, 78, 648–667. [Google Scholar] [CrossRef]

Philibert, C. Technology Roadmap: Concentrating Solar Power—Google Académico. Available online: https://scholar.google.com/scholar_lookup?title=Technology%20road%20map%3A%20Concentrating%20Solar%20Power&author=IEA&publication_year=2010 (accessed on 20 April 2020).

Purohit, I.; Purohit, P.; Shekhar, S. Evaluating the potential of concentrating solar power generation in Northwestern India. Energy Policy 2013, 62, 157–175. [Google Scholar] [CrossRef]

Belgasim, B.; Aldali, Y.; Abdunnabi, M.J.; Hashem, G.; Hossin, K. The potential of concentrating solar power (CSP) for electricity generation in Libya. Renew. Sustain. Energy Rev. 2018, 90, 1–15. [Google Scholar] [CrossRef]

Ling-zhi, R.; Xin-xuan, Y.; Yu-zhuo, Z.; Yu-zhuo, Z. Cost-benefit evolution for concentrated solar power in China. J. Clean. Prod. 2018, 190, 471–482. [Google Scholar] [CrossRef]

Dieckmann, S.; Dersch, J.; Giuliano, S.; Puppe, M.; Lüpfert, E.; Hennecke, K.; Pitz-Paal, R.; Taylor, M.; Ralon, P. LCOE reduction potential of parabolic trough and solar tower CSP technology until 2025. In Proceedings of the AIP Conference, Kedah, Malaysia, 3–5 April 2017; AIP Publishing LLC: Melville, NY, USA, 2017; Volume 1850, p. 160004. [Google Scholar]

Simsek, Y.; Mata-Torres, C.; Escobar, R.; Cardemil, J.M. Incentives and financial conditions effect analysis on levelized cost of electricity (LCOE) and government cost for concentrated solar power (CSP) projects in Chile. In Proceedings of the AIP Conference, Surakarta, Indonesia, 15 May 2018; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 2033, p. 120005. [Google Scholar]

Guédez, R.; Topel, M.; Spelling, J.; Laumert, B. Enhancing the Profitability of Solar Tower Power Plants through Thermoeconomic Analysis Based on Multi-objective Optimization. Energy Procedia 2015, 69, 1277–1286. [Google Scholar] [CrossRef]

Emes, M.J.; Arjomandi, M.; Nathan, G.J. Effect of heliostat design wind speed on the levelised cost of electricity from concentrating solar thermal power tower plants. Sol. Energy 2015, 115, 441–451. [Google Scholar] [CrossRef]

4echile Chile es el país Con la Mayor radiación del Mundo. Available online: http://4echile.cl/chile-pais-la-mayor-radiacion-del-mundo/ (accessed on 30 September 2019).

Marzo, A.; Zarzalejo, L.F.; Ibarra, M.; Navarro, A.A.; Soto, G.; Ramirez, L.; Escobar, R.; Silva-Pérez, M. Towards the Chilean solar thermal potential knowledge for solar power tower plants. In Proceedings of the AIP Conference, Surakarta, Indonesia, 15 May 2018; AIP Publishing: Melville, NY, USA, 2018; Volume 2033, p. 170008. [Google Scholar]

Cerro Dominador | Energía inteligente para un futuro sostenible. Available online: https://cerrodominador.com/ (accessed on 21 April 2020).

Meybodi, M.A.; Beath, A.C. Impact of cost uncertainties and solar data variations on the economics of central receiver solar power plants: An Australian case study. Renew. Energy 2016, 93, 510–524. [Google Scholar] [CrossRef]

Ji, J.; Tang, H.; Jin, P. Economic potential to develop concentrating solar power in China: A provincial assessment. Renew. Sustain. Energy Rev. 2019, 114, 109279. [Google Scholar] [CrossRef]

Explorador Solar. Available online: http://www.minenergia.cl/exploradorsolar/ (accessed on 6 January 2018).

Servicio de Evaluacion Ambiental Declaracion de impacto ambiental planta de concentracion solar de potencia Copiapo solar. Available online: https://seia.sea.gob.cl/archivos/2014/10/16/DIA_PCSP_Copiapo_Solar_-_Capitulo_06.pdf (accessed on 16 April 2020).

Freeman, J.M.; DiOrio, N.A.; Blair, N.J.; Neises, T.W.; Wagner, M.J.; Gilman, P.; Janzou, S. System Advisor Model (SAM) General Description (Version 2017.9. 5); National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [Google Scholar]

Molina, A.; Falvey, M.; Rondanelli, R. A solar radiation database for Chile. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef] [PubMed]

Victor Estrada Estudio de las tasas de Ensuciamiento y Efectos en Espejos Plantas Concentradoras de Potencia; Universidad Tecnica Federico Santa Maria: Santiago, Chile, 2019.

Wagner, M.J.; Wendelin, T. SolarPILOT: A power tower solar field layout and characterization tool. Sol. Energy 2018, 171, 185–196. [Google Scholar] [CrossRef]

Karim, M.; Naamane, S.; Hassani, I.E.A.E.; Delord, C.; Belcadi, S.; Tochon, P.; Bennouna, A. Towards the prediction of CSP mirrors wear: Methodology of analysis of influencing parameters on the mirrors surface degradation: Application in two different sites in Morocco. Sol. Energy 2014, 108, 41–50. [Google Scholar] [CrossRef]

Musi, R.; Grange, B.; Sgouridis, S.; Guedez, R.; Armstrong, P.; Slocum, A.; Calvet, N. Techno-economic analysis of concentrated solar power plants in terms of levelized cost of electricity. In Proceedings of the AIP Conference, Kedah, Malaysia, 3–5 April 2017; AIP Publishing LLC: Melville, NY, USA, 2017; Volume 1850, p. 160018. [Google Scholar]

Abdelhady, S.; Borello, D.; Shaban, A. Techno-economic assessment of biomass power plant fed with rice straw: Sensitivity and parametric analysis of the performance and the LCOE. Renew. Energy 2018, 115, 1026–1034. [Google Scholar] [CrossRef]

Comite solar e innovacion energetica de Corfo Reporte de relacion y magnitud de costos de Inversion (Capex) y Operacion & Mantenimiento (Opex). Available online: https://www.comitesolar.cl/wp-content/uploads/2019/12/Reporte-Capex-Opex-Plantas-CSP-final-Publicado.pdf (accessed on 17 April 2020).

Giacomozzi., G.; Felipe, I. Factores Críticos en Diseño y Operación de Centrales CSP de Torre con Almacenamiento en Sales Fundidas en el Desierto de Atacama; Repositorio Académico Universidad de Chile: Santiago, Chile, 2017. [Google Scholar]

Coordinador Electrico, Subestaciones. Available online: https://infotecnica.coordinador.cl/instalaciones/subestaciones (accessed on 13 February 2020).

Expansión de Transmisión—Comisión Nacional de Energía. Available online: https://www.cne.cl/tarificacion/electrica/expansion-de-transmision/ (accessed on 13 February 2020).

Mapa Precio de Combustibles – Energía Abierta | Comisión Nacional de Energía. Available online: http://energiaabierta.cl/visualizaciones/mapa-precio-de-combustibles/ (accessed on 13 February 2020).

Murphy, L.M. Solar Energy Research Institute 1617 Cole Blvd; Solar Energy Research Institute: Golden, CO, USA, 1980. [Google Scholar]

Benammar, S.; Tee, K.F. Structural reliability analysis of a heliostat under wind load for concentrating solar power. Sol. Energy 2019, 181, 43–52. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Upcoming CSP events:

10th CSP Focus China 2020 (June 18-19, Beijing China)

5th CSP Focus MENA 2020(September 9-10,Dubai, UAE)

More CSP news and reports please visit www.cspfocus.cn

or CSP Focus social media on LinkedIn, Twitter, Facebook.

More from CSP Focus

NextDecision on Kuwait’s Shegaya renewable energy park in two weeks

Shams Concentrated Solar Power: Ten years of renewable energy, reducing emissions

Grasp the last chance! Few Speaker slots are available for CSP Focus China 2019, Mar.21-22 Beijing

Heliogen Is Bill Gates’ Latest Venture That Is Only Good For Oil & Gas

CSP capex costs fall by almost half as developers shift towards China and Middle East

Aalborg CSP among the Australian Clean Energy Council Award finalists

The impact of concentrated solar power in electric power systems in Chile

Leave your thoughts here

Reports(Member Only)

See more+-

CSP Focus Membership Proposals

We are now proposing CSP Focus Membership, hoping to better serve our members to keep pace with the latest updates of ongoing CSP projects worldwide, and to establish and maintain business relations with major shareholders of the projects. CSP Focus offers to Membership exclusive access to:1. Daily/Weekly update and analysis on CSP policies, projects, technologies, market trend and corporate relea

-

The Latest CSP Focus Monthly Update

Join CSP Focus Membership to Get the Latest CSP Focus Monthly Update December Edition.

-

CSP Project Monthly Update 2022 December Edition

CSP Focus is presenting CSP Project (China) Update 2022 December Edition.Detail report is available for CSP Focus Membership.

-

Presentations-CSP Focus China 2021

The Report is for CSP Focus Members only.

Upcoming Events

See more+-

12th CSP Focus China 2022

2022.04.21-22 Beijing

-

11th CSP Focus China 2021

2021.10.28-29 Beijing

-

10th CSP Focus China 2020

2020.10.22-23 Beijing, China

Project Updates

See more+-

Lanzhou Dacheng Dunhuang CSP Project

Asia Pacific-China,Operational,Parabolic Trough

-

Luneng Haixi 50MW Molten Salt Tower CSP Project

Asia Pacific-China,Operational,Power Tower

-

Dubai 950MW NOOR Energy 1 CSP+PV Project

MENA-UAE,Under construction,Power Tower

-

Power China Gonghe 50MW Molten Salt Tower CSP Project

Asia Pacific-China,Operational,Power Tower